PPVS Complete Facilities Management

Home > Facilities Management Services > Planned Maintenance >

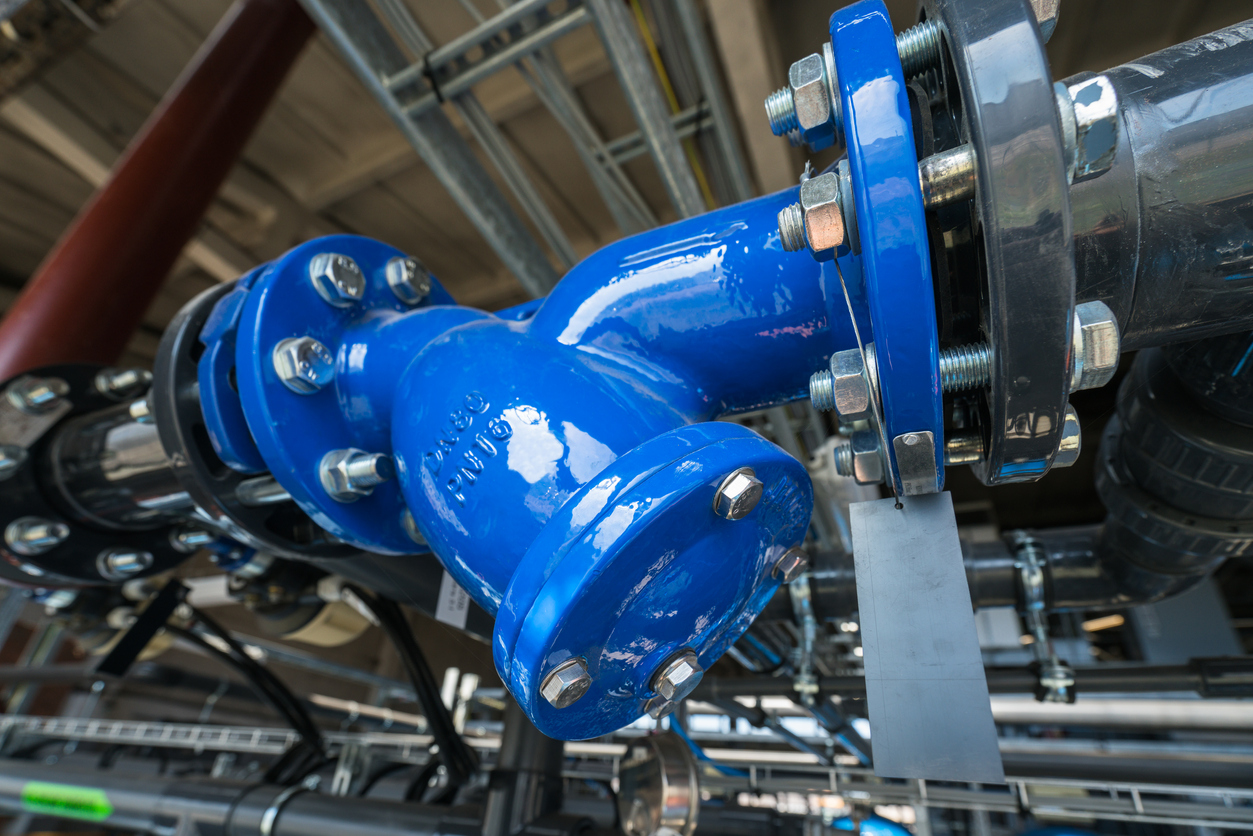

Water Hygiene Services & Solutions

Get in touchExperienced Water Treatment Services & Solutions

As a complete facilities management company we offer water treatment as part of our planned maintenance solution with a tried and tested waste water process. Here you can get information on:

- Our Water Treatment Process

- Coagulation and Flocculation

- Sedimentation

- Filtration

- Disinfection

- Waste Water Treatment

As an accredited ISO 9001 Quality Management Qualification holder and water treatment contractor, PPVS offers vital solutions in waste water treatment for all sectors including private, industrial and commercial properties with over 50 years of experience servicing more than 250 clients across 2,300 sites and counting in the UK.

Our Water Treatment Process

Waste water is treated using a complex portable blast furnace with a slag mineral filtering system that separates water molecules from solid materials and biological matter.

Polymers are used to coagulate any dirt in the water which is then processed into sedimentation tanks. From there the water flows through special filters before being disinfected.

Following the treatment process, the special filters are then cleaned with pressurised jets of water and involve double screening in order to remove excess matter such as biological waste and grit and the whole process can be repeated as necessary.

Waste Water Treatment

Treating water properly is vital and while the process seems simple, it is a logistical challenge that requires special machinery and professionally trained staff. The 4-step process includes:

- Coagulation and Flocculation; creates larger molecules called flocs.

- Sedimentation; settles flocs into sludge.

- Filtration; removes any remaining suspended impurities.

- Disinfection; applies chlorine to kill disease-causing microorganisms.

Water hygiene solutions can be used to provide clean and safe water to private clients, construction sites and industrial units to name a few, all through specialised water cleaning techniques that can be adapted for almost any property.

Talk To Us About Our Water Hygiene Services & Solutions.

Fill out the form for general inquiries or contact our team directly by calling the office directly using the numbers below.

Submit an enquiry

Coagulation and Flocculation

The raw water is processed with substances such as aluminum sulphate and sometimes with larger molecules called polymers that cause tiny molecules of dirt to stick to each other in a process called coagulation. Coagulation forces the smaller molecules to form into clumps which in turn stick to each other to form larger clumps called flocs. This process is known as flocculation.

Because the molecules become enlarged, they become heavier which helps with the next stage of the process when flocs pass through to the sediment tanks.

Sedimentation

Following the coagulation and flocculation process, water is processed into sedimentation tanks. Inside these tanks, water is slowly moved which, along with gravity, causes flocs (coagulated particles) to move to the bottom of the tanks and settle, where they form a sludge substance that is then processed to separate storage lagoons.

Sedimentation enhances the water treatment process by removing any particulates that might remain in the water. Essentially, this process removes the larger contaminants residing in the water before it is ready for filtration.

Filtration

Once flocs have been removed during the sedimentation process, water can then be passed through the filters. Blast furnace slag is used as the filtering medium during a percolation process but other materials such as gravel and anthracite are common. Slag is the byproduct of metal smelting, usually iron into steel and can contain metal oxides, silicon dioxide, sulfides and other metals.

Filtering is important to remove any leftover microscopic impurities in the water that would otherwise go unchecked. This is the final part of the filter process and therefore the last chance to catch any suspended particles.

Filters are routinely cleaned with high-pressure water and double screening techniques to maximise efficiency and hygiene.

Disinfection

As a final precaution, microbial contamination is prevented by disinfecting the water once it has been passed through the filter. Chlorine is almost always used since it is an effective eradicator of disease bacteria and microorganisms.

While adding chlorine to water might sound a little off-putting, it is perfectly safe for human use when below certain levels and when added to drinking water, the levels are low enough so as to be completely tasteless and undetectable.

Commercial Water Treatment Services Across the UK

Our team at PPVS has extensive experience providing comprehensive commercial water treatment services to businesses across the UK. We understand the importance of water hygiene solutions and maintaining clean and safe water systems for both employees and customers, and we’re dedicated to delivering high-quality solutions tailored to each individual business. No matter where you’re premises are located, we’re able to provide expert services and maintenance to ensure your water systems are running smoothly.

We ensure your water systems remain safe and free from microbiological contamination and Legionella bacteria. Our high-quality water hygiene solutions provide complete peace of mind for you and your business.

Fully Qualified With 50 Years Of Experience

We are experienced in providing a wide range of services from FM to construction for domestic, industrial and commercial sectors.

Water Hygiene Services & Solutions Frequently Asked Questions

What types of commercial premises do you work with? >

We have experience working with a wide range of commercial premises, including office buildings, shops, hotels, and more. Our team is equipped to handle the unique needs and requirements of each type of business and will provide tailored services accordingly.

Do you offer emergency services? >

At PPVS, we understand that emergencies can happen at any time. That’s why we offer emergency services for our clients in case of unexpected issues with their water systems. Our team is always ready to respond quickly and efficiently to ensure your business is back up and running as soon as possible.

How often should my water systems be maintained? >

The frequency of maintenance for your water systems depends on various factors, including the type of business and the size of the premises. Our team will work with you to create a customized maintenance plan that suits your specific needs and ensures your water systems are always in top condition.

Customer Focused Services

We understand that our customers are at the heart of everything we do, and we are dedicated to providing a service that meets their needs. We work closely with our clients to ensure that they’re happy with the results we deliver, and we’re always looking for ways to improve our service. We believe that communication is key, and we will always keep you updated on the progress of your project.

Operations Helpdesk with CAFM Reporting

Our helpdesk Operations Department provides 24/7 maintenance and support services for clients’ property portfolios across the UK. We have FM services with Project, Contract, and Account Managers ensuring smooth operations and compliance. Through our daily operations, we run reports to monitor spending, outstanding works, security, and potential projects, aiming to reduce unnecessary call-outs and save money. In FM, we use CAFM software to centralise facilities services, generate reports, and track SLA compliance. Clients can access the system through a client portal to review works and reports.

Get in touch to see how we can help with your Facilities Management.

For general enquiries please fill out the form and our team will be back in touch. Or give us a call or email using the details below.